Main Features

Frequency Hz 50

Voltage V 400

Power factor cos ϕ 0.8

Phase 3

Power Rating

Emergency Standby Power ESP kVA 22.00

Emergency Standby Power ESP kW 17.60

Prime power PRP kVA 20.03

Prime power PRP kW 16.02

Ratings definition (ISO-8528)

ESP - Emergency Standby Power:

It is the maximum power available during a variable electrical power sequence, under the stated

operating conditions, for which a generating set is capable of delivering in the event of a utility power

outage or under test conditions for up to 200 h of operation per year with the maintenance intervals

and procedures being carried out as prescribed by the manufacturers. The permissible average power

output over 24 h of operation shall not exceed 70 % of the ESP.

PRP - Prime Power:

It is defined as being the maximum power which a generating set is capable of delivering continuously

whilst supplying a variable electrical load when operated for an unlimited number of hours per year under

the agreed operating conditions with the maintenance intervals and procedures being carried out as

prescribed by the manufacturer. The permissible average power output over 24 h of operation shall not

exceed 70 % of the prime power.

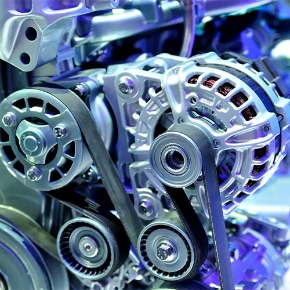

Engine specifications

Engine Brand Perkins

Model 404A-22G1

[50Hz] Exhaust emission level Non Emission

Certified

Engine cooling system Water

Nr. of cylinder and disposition 4 in line

Displacement cm³ 2216

Aspiration Natural

Speed governor Mechanical

Prime gross power PRP kW 18.7

Maximum gross power LTP ESP kW 20.6

Oil capacity l 10.6

Coolant capacity l 7

Fuel Diesel

Specific fuel consumption 75% PRP g/kWh 238

Specific fuel consumption PRP g/kWh 237

Starting system Electric

Starting engine capability kW 2

Electric circuit V 12

Engine Equipment

Standards

The above ratings represent the engine performance capabilities to conditions

specified in ISO 8528/1, ISO 3046/1:1986, BS 5514/1

Fuel system

Rotary type pump

Lube oil system

Wet steel sump with filler and dipstick

Filter

• Fuel filter

• Air filter

• Oil filter

Cooling system

• Mounted radiator

• Thermostatically-controlled system with belt driven coolant pump and pusher fan

Alternator Specifications

Alternator Leroy Somer

Model LSA40M5

Voltage V 400

Frequency Hz 50

Power factor cos ϕ 0.8

Poles 4

Type Brushless

Voltage tolerance % 0.5

Efficiency @ 75% load % 87.7

Class H

IP protection 23

SPECIALLY ADAPTED TO APPLICATIONS

The LSA 40 alternator is designed to be suitable for typical generator applications,

such as: backup, marine applications, rental, telecommunications, etc.

TOP OF THE RANGE ELECTRICAL PERFORMANCE

● Class H insulation.

● Standard 12 wire re-connectable winding, 2/3 pitch, type no. 6.

● High efficiency and motor starting capacity.

● R 791 interference suppression conforming to standard EN 55011 group 1 class B

standard for European zone (CE marking).

EXCITATION AND REGULATION SYSTEM

● Excitation system: AREP

REINFORCED MECHANICAL STRUCTURE

● Compact rigid assembly to better withstand generator vibrations.

● Steel frame.

● Aluminium flanges and shields.

● single-bearing designed to be suitable for heat engines.

● Half-key balancing

PROTECTION SYSTEM SUITED TO THE ENVIRONMENT

● The LSA 40 is IP 23.

● Winding Protection for clean environments with relative humidity ≤ 95%, including

indoor marine environments.

COMPLIANT WITH INTERNATIONAL STANDARDS

The LSA 40 alternator conforms to the main international standards and regulations:

- IEC 60034, NEMA MG 1.32-33, ISO 8528-3, CSA C22.2 n°100-14, UL 1146 (UL 1004

on request), marine regulations, etc.

It can be integrated into a CE marked generator.

The LSA 40 is designed, manufactured and marketed in an ISO 9001 environment and

ISO 14001.

Genset equipment

BASE FRAME MADE OF WELDED STEEL PROFILE, COMPLETE WITH:

• Anti-vibration mountings properly sized

• Welded support legs

PLASTIC FUEL TANK WITH THE FOLLOWING COMPONENT:

• Filler neck

• Air breather (ventilation pipe)

• Minimum fuel level sensor

OIL DRAININ PIPE WITH CAP:

• Oil draining facilities

ENGINE COMPLETE WITH:

• Battery

• Liquids (no fuel)

CANOPY:

• Soundproof canopy made up of modular panels, realized with zinced steel as

treatment against corrosion and aggressive conditions, properly fixed and sealed

allowing a full weatherproof enclosure.

• Easy access to the genset for maintenance purposes thanks to: Wide lateral access

doors fixed by stainless steel hinges and provided with plastic lockable handles and

internal perforated galvanized steel-sheet; Detachable panels, with screws holes

protected by rubber tap.

• Control panel protection door provided with suitable window and lockable handle.

• Lateral air inlet opening properly protected and soundproofed. Exhaust air outlet from

the roof, trough wet section protected by proper grid.

• Single detachable lifting eye placed on the roof.

SOUNDPROOF:

• Noise attenuation thanks to soundproofing material

• Efficient residential silencer placed inside the canopy

Dimensional data

Length (L) mm 1800

Width (W) mm 850

Height (H) mm 1260

Dry weight kg 702

Fuel tank capacity l 68

Fuel tank material Plastic

Autonomy

Fuel consumption @ 75% PRP l/h 3.97

Fuel consumption @ 100% PRP l/h 5.27

Running time 75% PRP h 17.13

Running time 100% PRP h 12.90

Noise level

Guaranteed noise level (LWA) dB(A) 87

Noise pressure level @ 7 m dB(A) 58

Installation data

Exhaust gas flow m³/min 3.64

Exhaust gas temperature °C 445

Electrical Data

Battery capacity Ah 80

Max current A 31.76

Circuit breaker A 32

Control panel availability

AUTOMATIC CONTROL PANEL ACP

MCP - Manual control panel

Mounted on the genset and complete of: analogue instrumentation, control, protection

of the generating set, protected through door with lockable handle.

INSTRUMENTATION (ANALOGUE)

• Voltmeter (1 phase)

• Ammeter (1 phase)

• Hours-counter

COMMANDS

• Start/stop selector switch with key (Glow plugs preheating function also included).

• Emergency stop button installed on canopy side.

PROTECTION WITH ALARM

• Low fuel level

• Battery charger failure

• low oil pressure

• high engine temperature

• Earth Fault.

PROTECTIONS WITH SHUTDOWN

• Low fuel level

• Battery charger failure

• low oil pressure

• high engine temperature.

• Circuit breaker protection: III poles

• Emergency stop button

OTHERS

• Panel protected through door with lockable handle.

OUT PUT PANEL MCP

Power cables connection to Circuit Breaker.

Socket kit Standard

Thermal protections

3P+N+T CEE 400V 32A n 1

3P+N+T CEE 400V 16A n 1

2P+T CEE 230V 16A n 2

230V 16A SCHUKO n 1